Services

Featuring Rapid Turnaround and High Quality

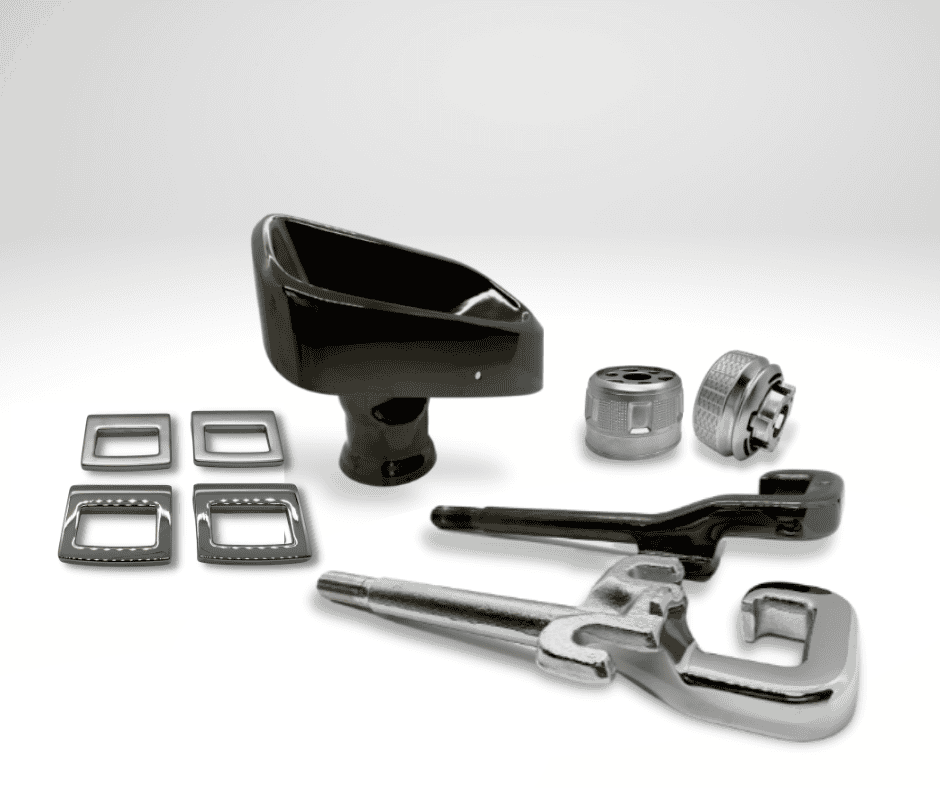

Specialty Finishes & Process

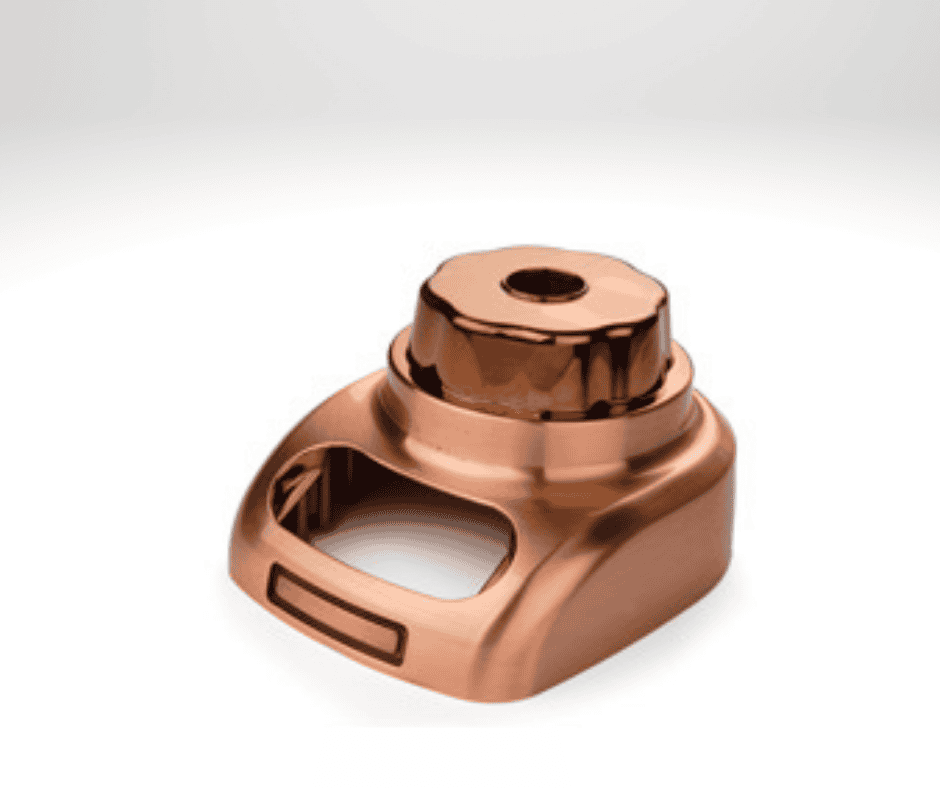

Fashion Finishes

Master Finish offers a wide variety of decorative colors and options using our copper, nickel, and chrome plating baths we can adjust the gloss, and darkness of your product to suit your needs

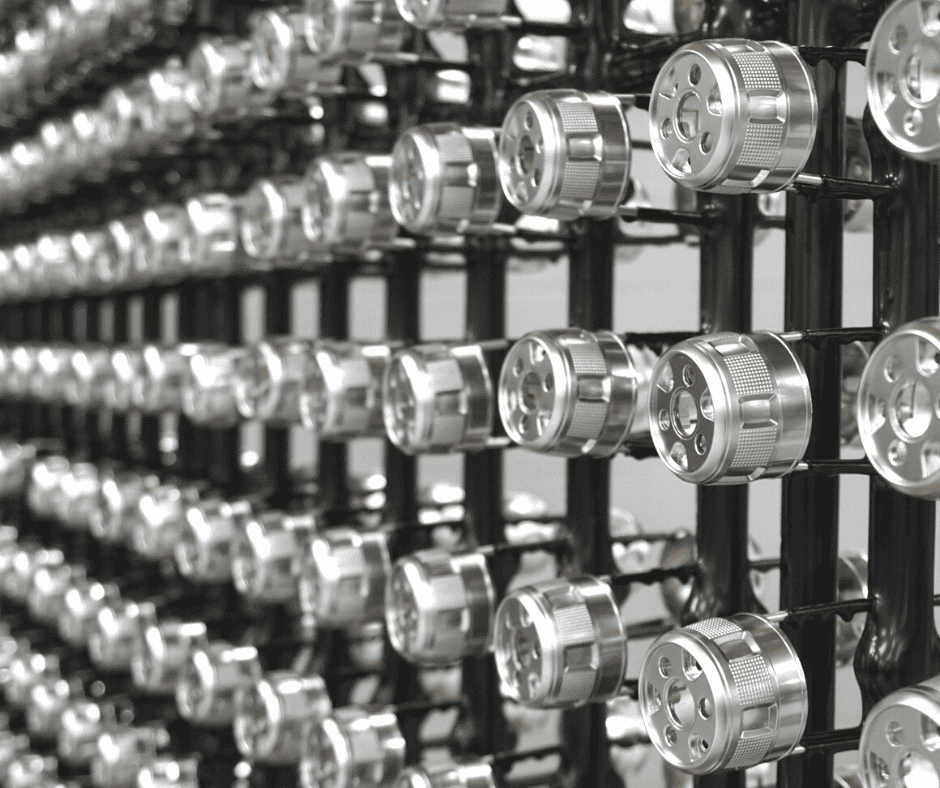

Automated Process Control

Master Finish operates three fully automated plating lines automation in plating allows us to keep our quality high, costs low and provide the best customer experience to our valued supply chain partners.

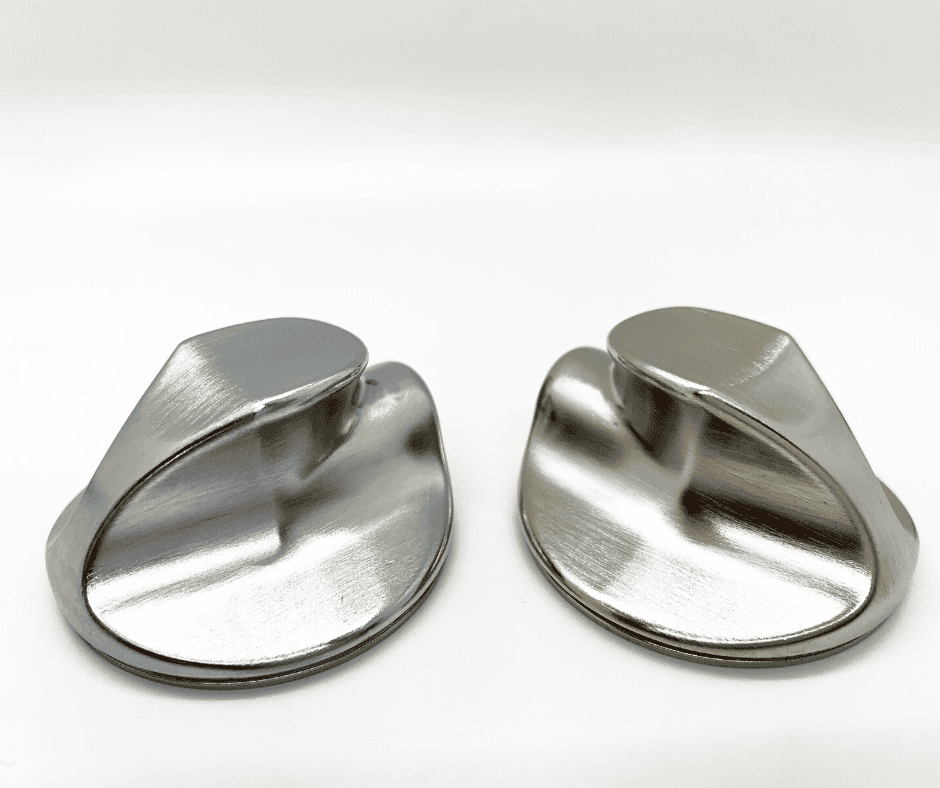

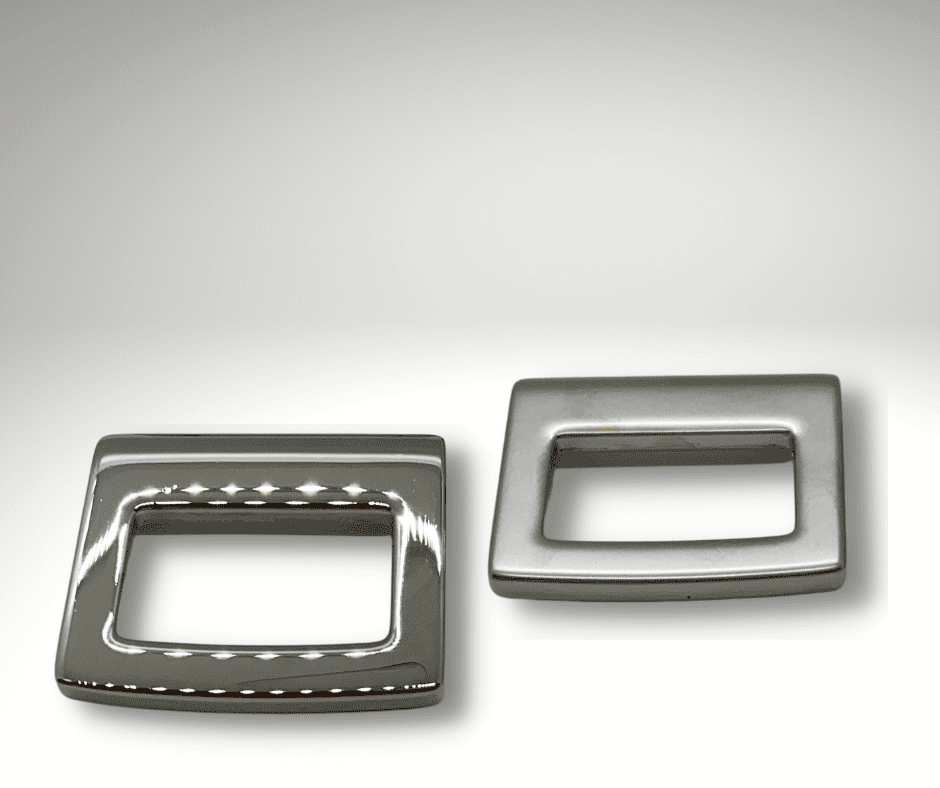

Satin Chrome

Achieving a satin finish at Master Finish can be done in multiple ways with or without a grain pattern. We can help you match the finish you are looking to achieve

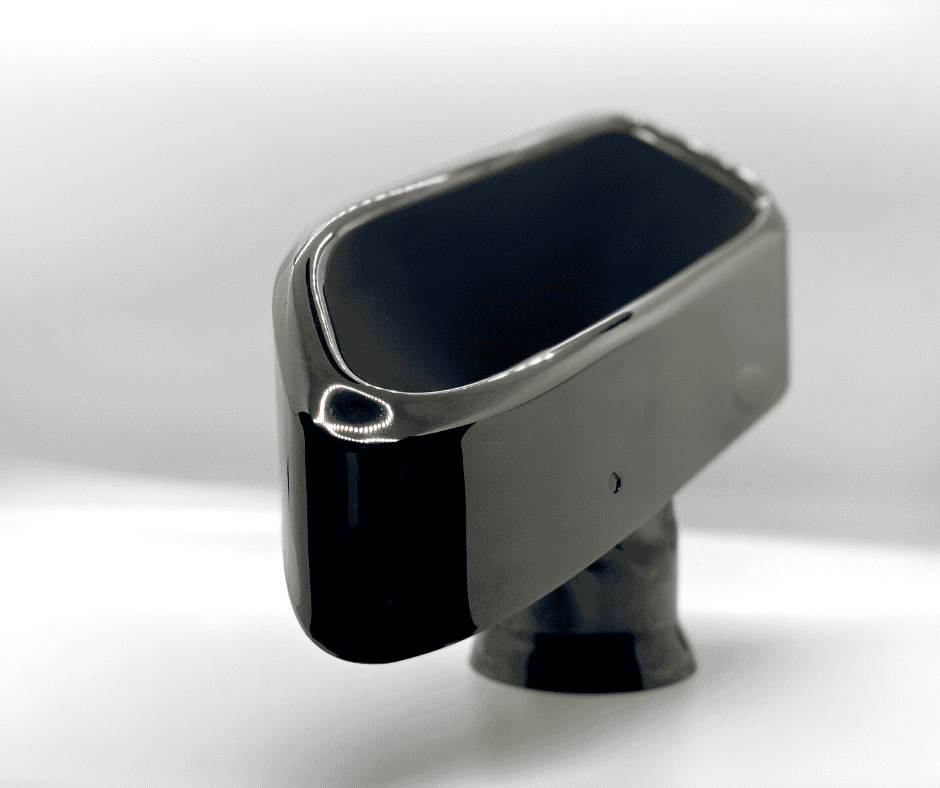

Trivalent Chromium Technology

Master Finish believes the future is in the more environmental technology offered by Trivalent Chrome plating bath chemistry. We offer plating using both trivalent and traditional hexavalent plating baths to serve our customers with the options they desire. All the Black and dark chromes we offer use the Trivalent Chrome technology.

ReplaChrome®

Current technologies do not allow for production barrel plating using a chromium deposit. Master Finish uses a proprietary plating bath we call Replachrome as a substitute in our barrel plating line. It gives parts a color match close to chrome at the cost effective price you get from a barrel plating proces

Metal Plating Service

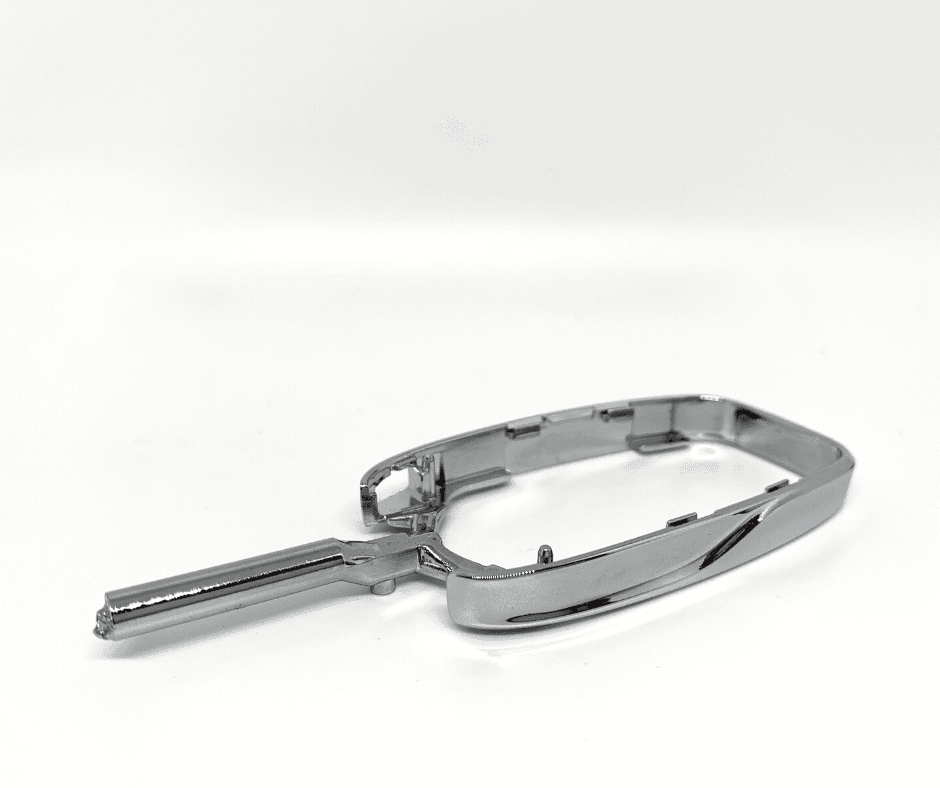

Decorative Chrome Plating

Bright decorative chrome services provide our customers with parts finished to meet the stringent class A surface finish requirements of most industries including automotive, motorcycle, consumer products, hardware, and plumbing.

Dark Chrome Plating

Our company offers both a smoky chrome and a very dark chrome finish option using MacDermid – Enthone’s Starlite and Eclipse plating chemistry.

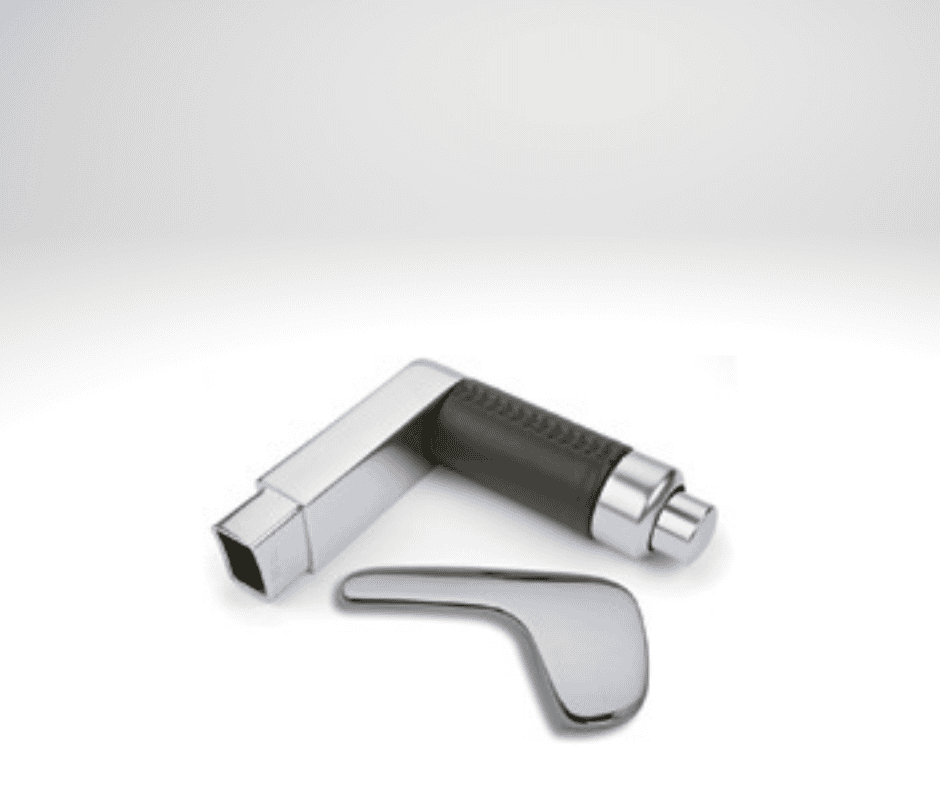

Satin Chrome Plating

Master Finish can provide either a brushed satin nickel finish or a satin nickel finish using the MacDermid Enthone Satin nickel chemistry. Both offer a finish that diffuses the light giving a range of appearances between mirror reflective and dull matte that is customizable to your needs

Copper Plating

Copper plating is our best coating for leveling and removing most of the minor surface imperfections on parts. We offer both cyanide based and acid based copper plating baths to suit your plating needs

Nickel Chrome Plating

Master Finish specializes in a wide variety of Nickel Chrome plating options to meet the appearance and corrosion protection needs of your product.

Barrel Nickel Plating

Barrel Nickel Plating on small steel, copper, and brass components. The barrel nickel plate provides a bright attractive corrosion resistant appearance. Barrel plating is a far more cost effective process for this type of part.

Rack Nickel Plating

Our rack nickel plating allows us to process parts made from Steel, Stainless, copper, brass, and zinc die cast parts with multiple layers of nickel if necessary to meet your appearance and corrosion protection needs.

Preplate Finishing

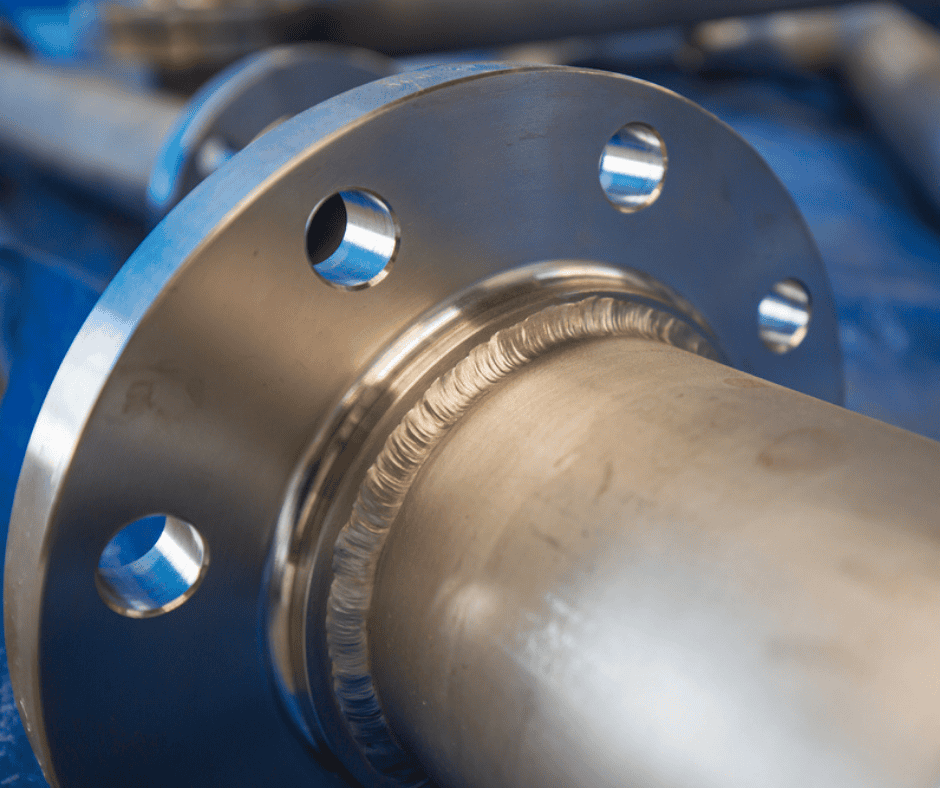

Passivation of Stainless Steel

The complete array of metal finishing services available at Master Finish Company includes passivation of stainless steel. Through passivation, the full corrosion-resistant qualities of stainless steel are restored through the chemical treatment of the surface.

METAL POLISHING & BUFFING

Class-A metal surfaces often require polishing and buffing prior to decorative plating. Abrasive belt polishing is used to remove parting lines from castings and burrs from steel stampings. Show surfaces of the metal are then buffed to a smooth high luster by rouge compounds applied under the pressure of rotating fiber wheels.

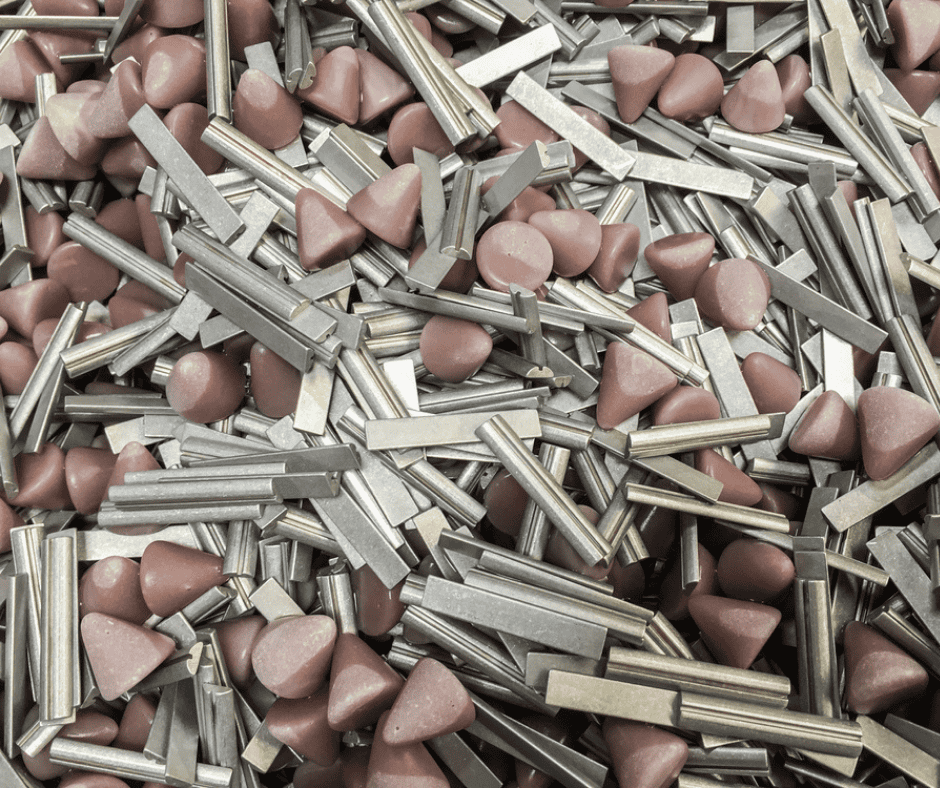

Vibratory Finishing

The comprehensive metal finishing services available from Master Finish Company includes vibratory finishing. Vibratory finishing is a process in which smaller parts or components are placed in a tub or bin with burnishing media, which can include ceramics, plastics, granite, steel balls, or organic media such as ground walnut shells or corn cobs. An asymmetrically weighted motor then creates vibration to achieve the desired results as components and media scrub together.

Postplate Finishing

Dehydrogenation Bake Off

The postplate metal finishing services of Master Finish Company includes dehydrogenation bake off. Heat-treated steel components may require dehydrogenation bake off immediately after plating to remove hydrogen from the part and prevent embrittlement. Heat-treated parts are baked immediately after plating to remove hydrogen molecules from the metal, providing stability and durability.

Paint Finishing of Plated Metal Components

Master Finish Company’s metal finishing services also include paint finishing after the plating process. A wide variety of paint finish topcoats are available to match a broad range of coating chemistries and curing temperature needs. This flexibility allows us to deliver durable, hard coatings on almost any decorative plated part.

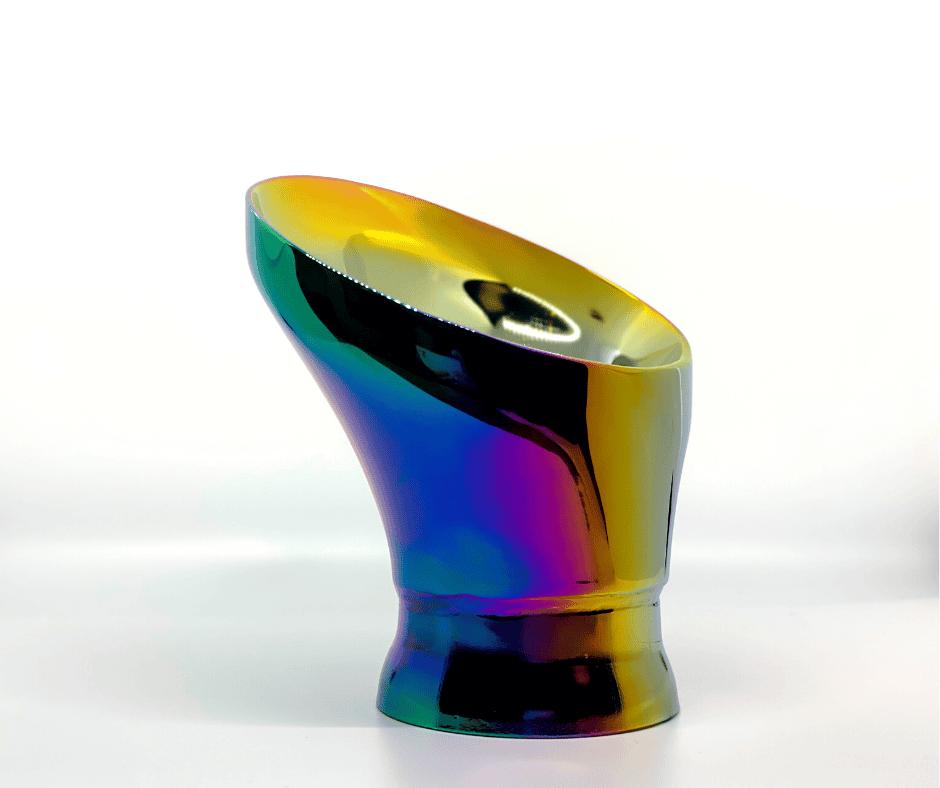

PVD Coating Topcoat Finishing

The topcoat finishing services available at Master Finish Company include PVD Coating. PVD (Physical Vapor Deposition) coating is the application of a hard, thin film to a plated surface to add both decorative and functional properties, depending upon the application.

Restoration & Refinishing

As the saying goes we can not please everyone all the time! Our operations are geared to serve other business customers with production needs. Restoration work requires a different skillset and resources. Here are some that we have heard do a great job!

Request a Quote

For pricing on your project please send your part drawings, plating specifications, and production volumes to sales@masterfinishco.com.

Need more info?

Call us (616) 245-1228 or Contact Us online