From September 14-19, 2024, Master Finish proudly participated in the International Manufacturing Technology Show (IMTS) held at McCormick Place in Chicago. As one of the largest industrial trade shows in the world, IMTS 2024 brought together 89,020 attendees and...

Blog

Join Master Finish at IMTS 2024 in Chicago – Discover the Future of Manufacturing Innovation!

Master Finish is excited to announce that we will be exhibiting at the InternationalManufacturing Technology Show (IMTS), held from September 9-14, 2024, at McCormick Place in Chicago. This event is one of the largest manufacturing trade shows in the world, and we...

Passivation Process: Nitric Acid vs. Citric Acid

Master Finish offers passivation services using Nitric acid. This service uses the chemistry that we have in place for cleaning and stripping the plating racks we use for our chrome plating lines. Passivation is a chemical process used to improve the corrosion...

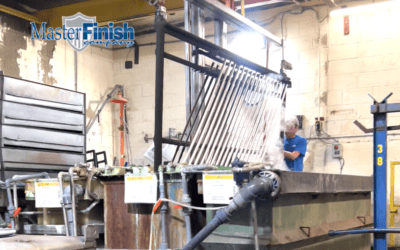

Enhancing Efficiency and Safety: The Advantages of a Central Chemical Feeder System in Electroplating

In the intricate world of electroplating, every detail matters. From the composition of the chemicals to the efficiency of the equipment, each element plays a crucial role in achieving high-quality finishes and ensuring operational safety. One often overlooked, yet...

65 Years of Excellence and Environmental Stewardship

As we commemorate the 65th anniversary of Master Finish Company, it’s a perfect opportunity to celebrate our rich heritage, our unwavering commitment to quality, and our deep-seated respect for the environment. Our journey, deeply interwoven with the fabric of Grand...

An Interview with John Mulder, Master Finish

BY SCOTT FRANCIS Editor-In-Chief, Gardner Business Media John Mulder, president of Master Finish of Grand Rapids, Mich., discusses his company’s experience with trivalent chromium and offers advice for those thinking of transitioning their current hexavalent chromium...

Decoding Chrome Plating: A Guide to Decorative vs. Industrial Chrome Plating

Understanding the Basics of Decorative Chrome Plating Before we dive into the specifics, let’s grasp the fundamentals. Chrome plating is a process that involves electroplating a thin layer of chromium onto a metal object. This not only enhances the appearance but also...

Understanding the Difference Between Electroless and Electrolytic Nickel Plating

When it comes to metal plating, nickel is one of the most commonly used materials due to its excellent corrosion resistance and versatile properties. However, there are different techniques for applying nickel plating, with two primary methods being electroless and...

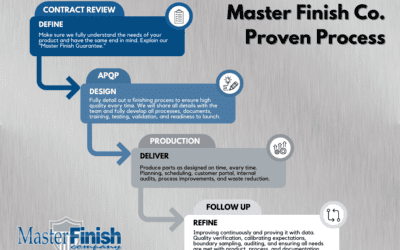

Proven Process

Master Finish has been on a journey using EOS (Entrepreneur Operating System) to manage all the critical elements of our business. We started on this Journey in 2016 and have found it instrumental to our success in so many ways. It helps set a framework in...

Streamlining Success

How Master Finish Implemented Automation to Improve Production and Boost Customer Satisfaction As companies in the manufacturing industry face increasing challenges with production labor, it is becoming more critical to automate tedious tasks that are currently being...