In the intricate world of electroplating, every detail matters. From the composition of the chemicals to the efficiency of the equipment, each element plays a crucial role in achieving high-quality finishes and ensuring operational safety. One often overlooked, yet pivotal, aspect is

the methodology of chemical delivery to the plating line.

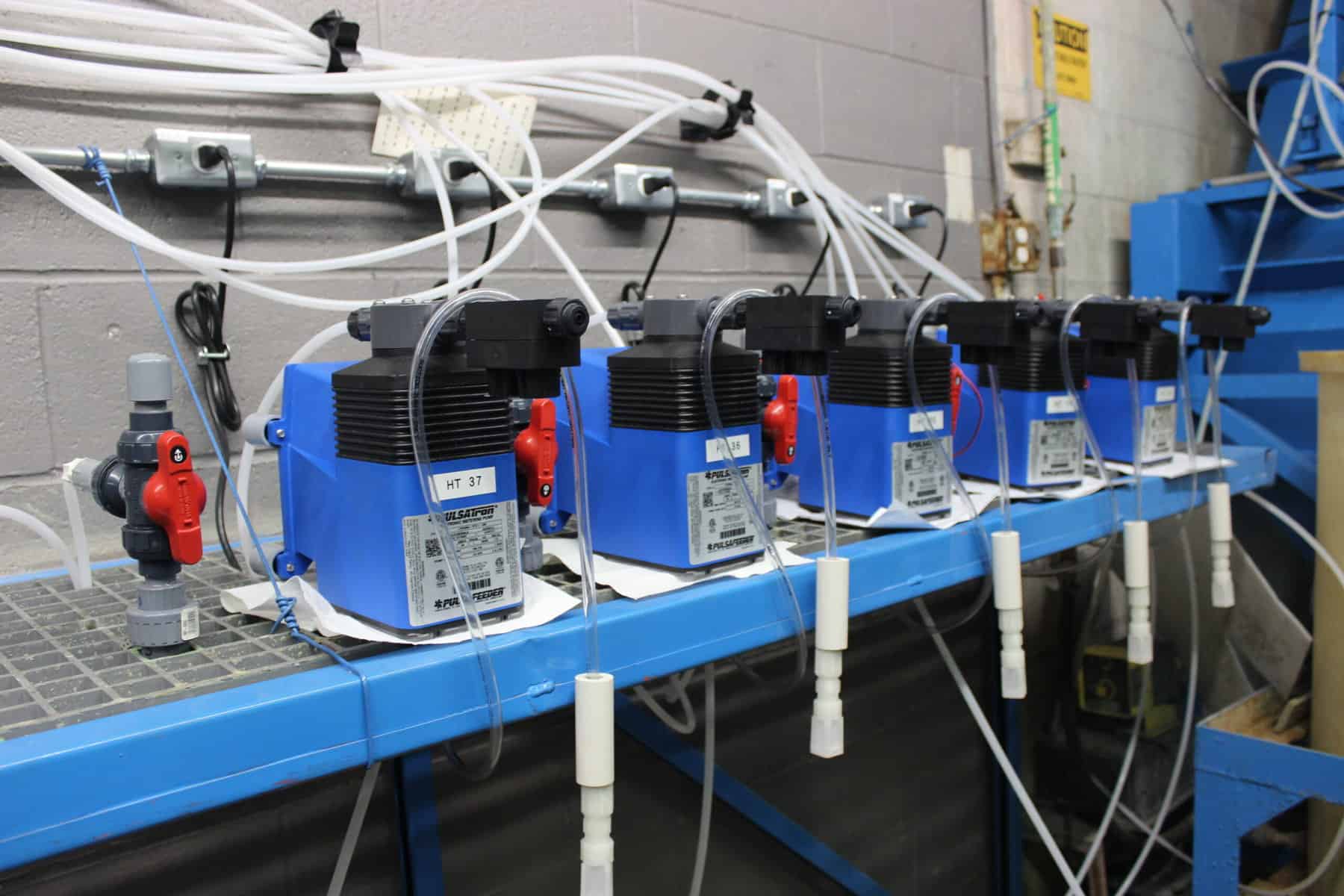

At Master Finish, we understand the significance of streamlining processes for optimal performance. That’s why we are in the process of implementing a new central chemical feeder system, revolutionizing our plating line operations.

Central feeding simplifies the workspace by eliminating clutter on the catwalk. Picture this: a clean, organized environment where technicians can navigate effortlessly, focusing on the task at hand with all the equipment pumps, feed chemicals, and testing equipment for calibration all

in one place and clearly organized and efficient. This not only enhances productivity but also reduces the risk of mistakes being made or worse like accidents, fostering an easier work area

and safer working environment for our team.

Moreover, standardizing the pumping equipment has proven to be a game-changer. With uniform machinery across the board, maintenance becomes a breeze. Technicians no longer need to grapple with a myriad of different systems; instead, they can efficiently troubleshoot and calibrate equipment with ease. This not only saves valuable time but also ensures consistent

performance, optimizing feed rates to meet the demands of the plating line seamlessly.

But, the benefits don’t end there. Our new central feeder system has significantly enhanced chemical maintenance protocols. By streamlining procedures, we expect a marked improvement in bath performance. The system facilitates quicker checks and validations, empowering our team to stay on top of maintenance tasks with precision and efficiency they could not perform

with the old system. This not only reduces the labor needed in the chemical feeder

maintenance, but will allow our team to perform more frequent checks with the reduced workload, and allow for quicker response time to the data being collected.

Last but not least, safety is paramount at Master Finish. With the implementation of the central feeder system, we’ve elevated our safety standards to new heights. By simplifying labor-intensive tasks and minimizing manual handling of chemicals, we’ve mitigated potential risks, ensuring the well-being of our valued team members.

In conclusion, the introduction of a central chemical feeder system has heralded a new era of efficiency and safety at Master Finish. By embracing innovation and prioritizing excellence in every aspect of our operations, we’re setting new benchmarks in the world of electroplating.

Join us on this transformative journey as we continue to push the boundaries of possibility and redefine industry standards, one impeccable finish at a time.