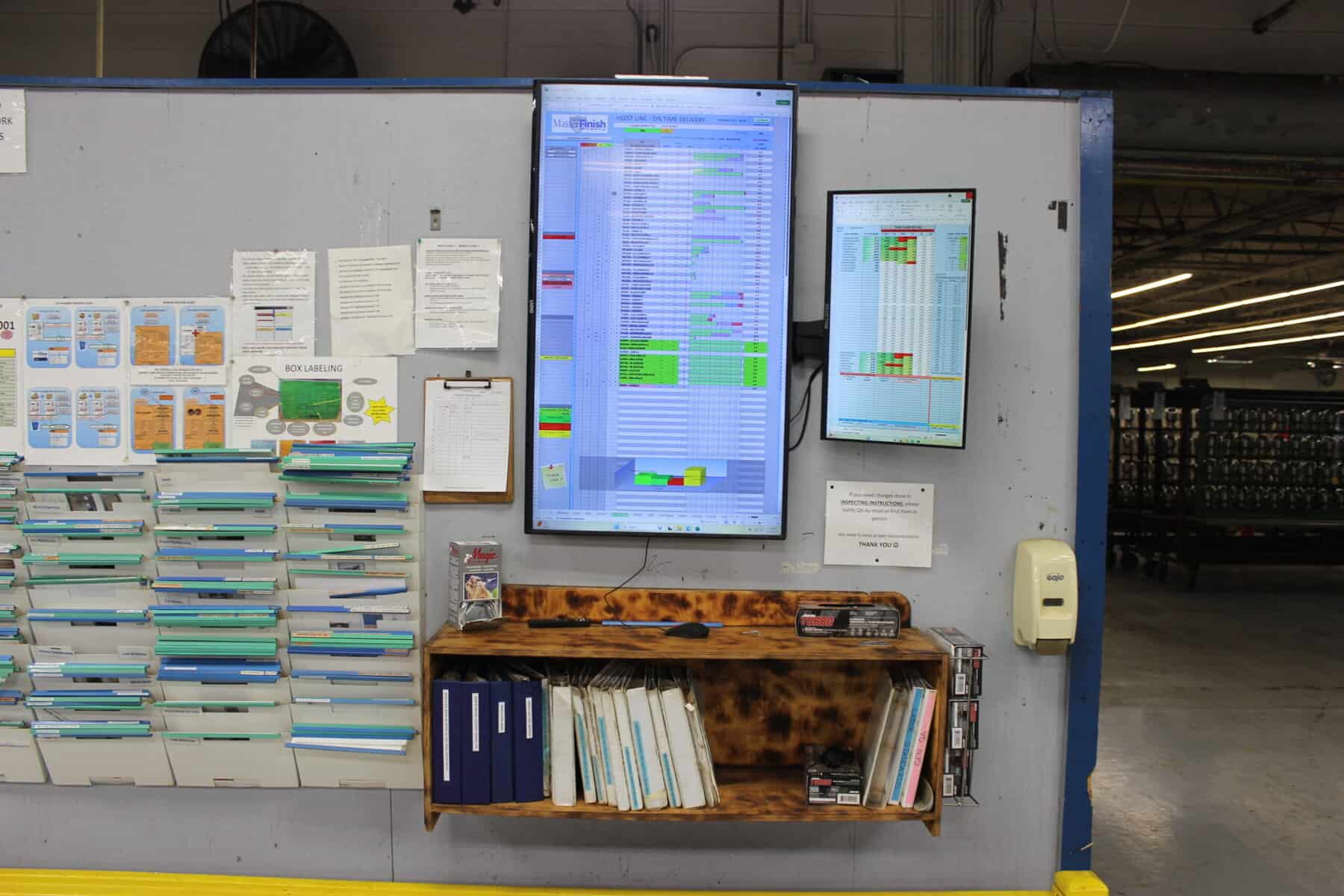

In a busy manufacturing environment, staying organized and keeping everyone on the same page is essential. At Master Finish, we’ve developed a Mission Control Center inside our facility to do just that. Acting as the hub of communication and planning, the Mission Control helps our team manage workloads, track progress in real time, and ensure that every part meets customer requirements. It’s where organization meets efficiency, and it plays a key role in delivering consistent quality to our customers.

At the heart of the Mission Control is our large monitor, which displays the weekly dashboard. This live tracker is updated daily so that every team member can see exactly what’s happening on the production floor.

Here’s what the dashboard provides:

- Weekly To-Do Lists: A clear overview of all jobs scheduled for completion.

- Job Progress: Real-time updates on how far along each job is and how quickly work is moving.

- Priorities at a Glance: Jobs marked as Hot Jobs are highlighted so the team knows what requires immediate attention.

- Clear Completion Signals: A green indicator means all necessary jobs are done for the day—a milestone the team strives to hit consistently.

The dashboard isn’t just a screen, it’s the pulse of our weekly workflow. By making information visible and accessible, it helps us stay aligned and proactive as jobs come in and go out.

Beyond the dashboard, the Mission Control also provides work instructions tailored for rackers and inspectors. These instructions are printed, labeled, and organized for every customer’s parts, ensuring that no detail is overlooked.

The work instructions outline:

- Inspection Requirements: Clear guidelines to ensure a 100% inspection of each part.

- Handling Techniques: Proper racking and un-racking methods, with notes on what to watch out for.

- Packaging Standards: Instructions for how parts should be packaged to meet each customer’s requirements.

By laying out these details in an easy-to-follow format, we keep our process efficient and consistent. Parts move seamlessly through the facility without unnecessary delays, and our customers benefit from reliable, high-quality results.

Keeping the Team Informed and the Process Flowing

The Mission Control represents more than just organization. It’s a symbol of how Master Finish values clarity, accountability, and teamwork. By combining live updates with detailed instructions, we give our employees the tools they need to succeed and keep our operations running at peak efficiency.

At Master Finish, we believe that when our team is informed and supported, our customers see the results. The Mission Control is just one way we bring that belief to life.