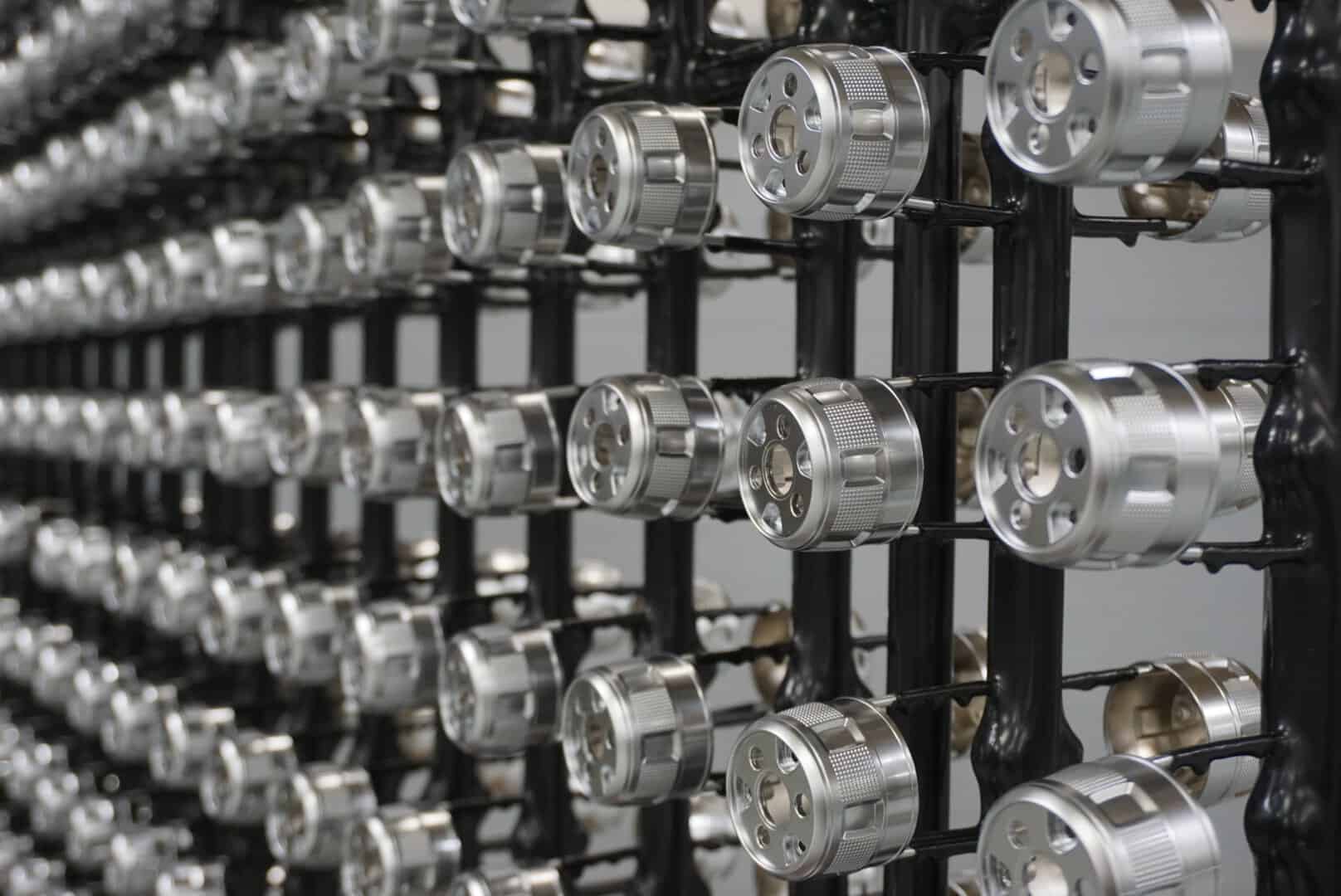

Automation

Automation vs. Manual Processing for data and traceability. Machine data available from automated plating lines helps the team at Master Finish diagnose and correct plating issues on the fly to reduce scrap. The data on each motion in the plating line is recorded and stored on our server network. The same is true of the power outputs from our rectifier units. Our team serializes the loads we process on our plating lines and provides a specific serial number called a load ID on the tags we place on the return packaging. If you are pulling parts out of a box that came from Master Finish we can use that ID number to provide you with all the processing details, and how they compare to the process standard for that product. For more information on our automating process, contact our team of experts at (616) 245-1228.