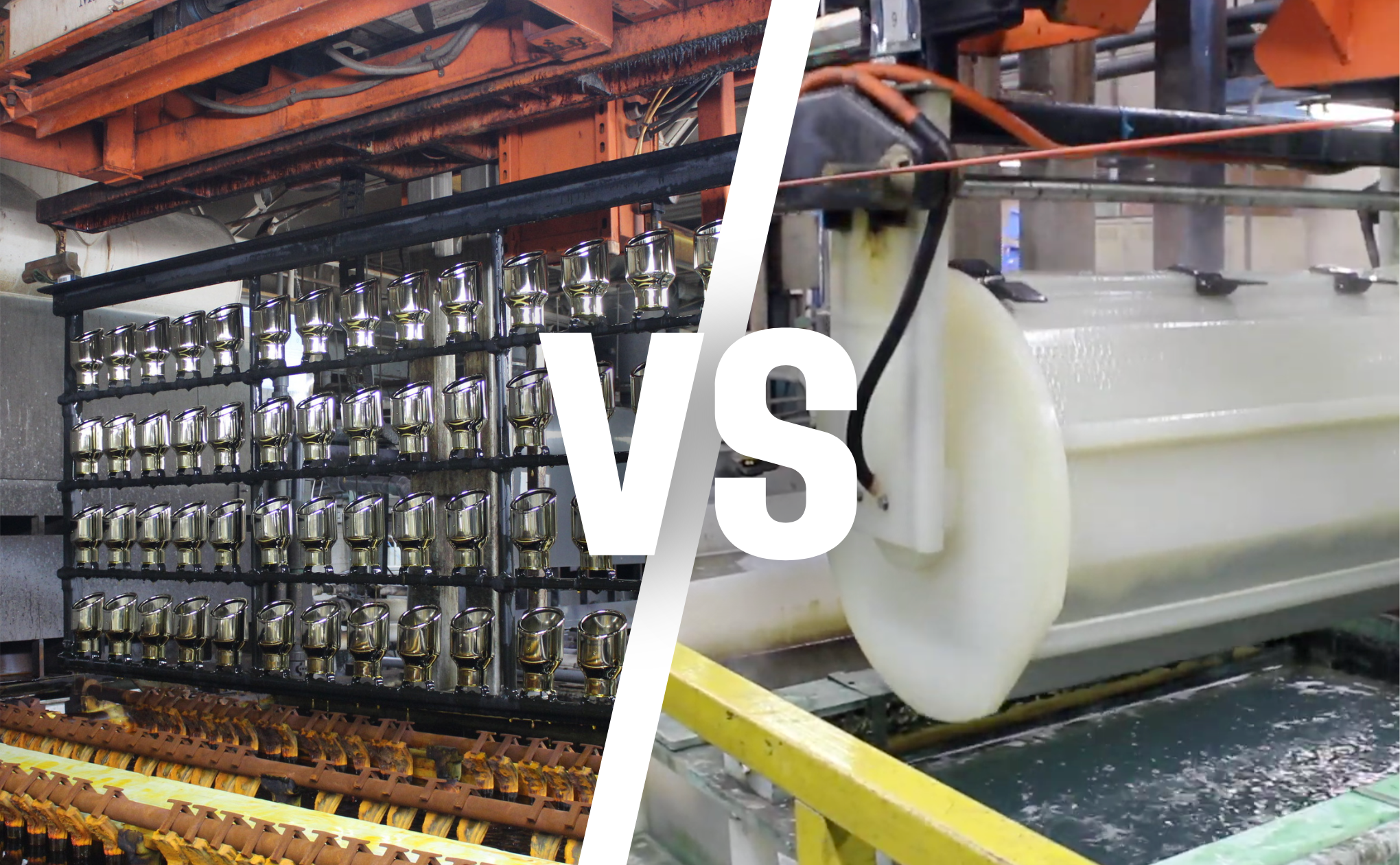

When it comes to electroplating, selecting the right process is essential for achieving optimal results. At Master Finish, we offer both rack plating and barrel plating, two widely used electroplating methods that serve different purposes. Understanding the differences between these processes can help manufacturers make informed decisions based on their specific part requirements, budget, and production volume.

What is Rack Plating?

Best For: Large, complex, or delicate parts requiring a precise finish.

How it Works:

Parts are individually mounted onto custom-designed racks that hold them in place during the electroplating process. This method ensures uniform coating thickness and minimizes damage to sensitive components.

Advantages of Rack Plating:

- Ideal for large, intricate, or delicate components.

- Provides even coating distribution for consistent quality.

- Protects fragile parts from excessive movement and potential damage.

Common Applications:

- Automotive trim and decorative hardware.

- High-end consumer products requiring flawless finishes.

- Components with precise dimensional tolerances.

What is Barrel Plating?

Best For: Small, durable, high-volume parts that can withstand tumbling.

How it Works:

Parts are placed in a rotating barrel, allowing them to tumble while being electroplated. This process is efficient for plating large batches of smaller components at once.

Advantages of Barrel Plating:

- Cost-effective for high-volume production.

- Provides consistent coating across many small parts.

- Reduces handling time and increases efficiency.

Common Applications:

- Fasteners, screws, and connectors.

- Small industrial and automotive components.

- High-volume parts with simple geometries.

How to Choose the Right Plating Method

When deciding between rack and barrel plating, consider these factors:

- Size & Shape – Large, complex parts are best suited for rack plating, while small, durable parts work well with barrel plating.

- Aesthetic Requirements – If a flawless finish is needed, rack plating is the better choice.

- Production Volume – High-volume production benefits from the efficiency of barrel plating.

- Budget – Barrel plating is typically more cost-effective for bulk orders, while rack plating is ideal for high-precision finishes.

Master Finish: Your Electroplating Partner

At Master Finish, we offer both rack and barrel plating solutions, customized to meet the needs of our clients across multiple industries. Whether you require a premium decorative finish or a cost-effective plating process for mass production, our team has the expertise to deliver superior results.

Contact us today to discuss your plating needs and find the best solution for your project.